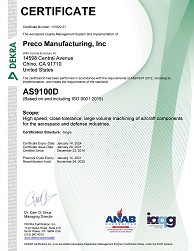

As an aerospace company, ISO 9001:2008 & AS9100 Rev C Registered, quality is at the core of

Preco’s success. We maintain precise traceability for all production processes compliant to the

most demanding customer and regulatory specifications. Our Continuous Flow Impregnation

system aids the process in the quality we strive to achieve to better serve our customers and to

overcome quality issues we have witnessed in the industry:

- Meticulous Receiving Inspection

- Resin Contamination Tests in all cavities (threads, bores,etc.)

- Effective Monitoring of Resins

- Tight Maintenance of Process Equipment

- Process effectiveness with FTT (first time through) in excess of 99.6%

Quality does not stop with process and equipment, it permeates throughout our business, using

only the highest quality materials in our vacuum impregnation system. Our sealants meet the

standards and requirements of ISO/TS 16949. Our sealants are also qualified and approved by

MIL-I-17563C and almost every major industrial, automotive and aviation OEM.

- Low surface tension sealants for effective penetration of micro-porosity

- Black Light Sensitive Sealants to Readily Detect Contamination

At Preco we seek to become the premier supplier to every customer we serve, weather it is in

the aerospace, commercial or industrial sector. We've become sensitized not only to our customers

but to our surroundings as well and we strive to apply our quality principles not only to

better serve our customers, but to maintain a balance with our environment:

- Green Technology

- Water recycling systems for zero discharge

- All resins used on your parts are organic & environmentally friendly

- Sustainable – we conserves resources including labor, water and electricity

- Plans to reach 50% alternative Energy Use